Sandblasting Cabinet

- Homepage

- Sandblasting Cabinet

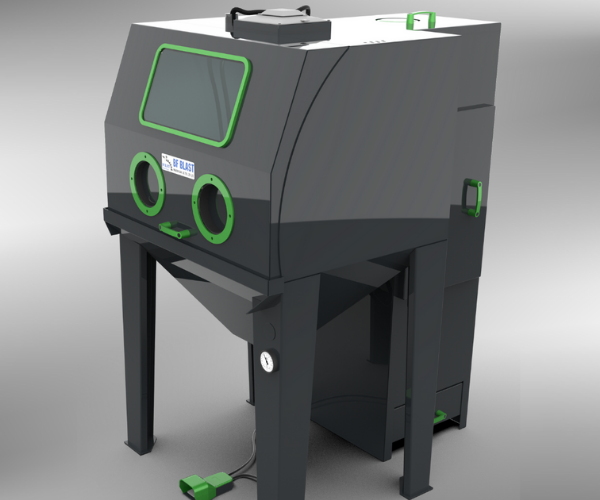

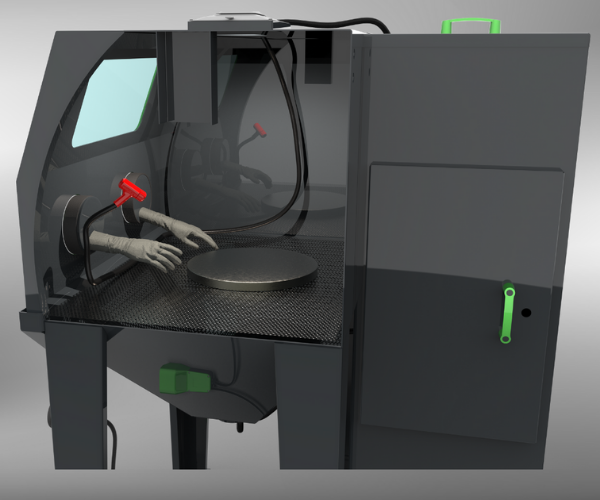

Sandblasting Cabinets are designed for dust-free sandblasting of small and medium-sized parts in the cabinet. Air consumption is less compared to pressurized cabins. Thanks to the cartridge filter coupled to the back of the cabinet, a clear view is provided during sandblasting.

Sandblasting Cabinet: Precision Surface Refinement*

The Sandblasting Cabinet is a game-changer when it comes to surface cleaning and preparation. This high-precision cabinet offers unmatched capabilities, from industrial-scale projects to delicate craftsmanship, ensuring surfaces are impeccably refined.

*Why Choose the Sandblasting Cabinet?*

1. Clean and Dust-Free Environment: Equipped with an integrated dust extraction system, it minimizes dust and particle dispersion, boosting work efficiency and maintaining workplace health.

2. Effective Sandblasting: Employing high-pressure abrasive blasting technology, it expertly removes even the most stubborn dirt and paints, leaving surfaces impeccably prepared.

3. Precise Control: Advanced control systems provide precise command over the sandblasting process, ensuring safe and effective treatment of a variety of surfaces.

4. Versatile Applications: Suitable for metal, wood, plastic, and more, it’s the go-to solution for various materials, making it a versatile choice.

Steel grit/steel ball-like granules are not used in vacuum blast cabinets!

Only suitable for use with aluminum oxide, silica, garnet, glass ball, and plastic granules!

*Why Choose Us?*

We are specialists in Sandblasting Cabinet technology and uphold the following principles:

– Technological Excellence: Employing the latest sandblasting technology, we deliver top-notch results.

– Customer Satisfaction: We understand customer needs and provide the most suitable solutions.

– Experience and Reliability: With years of experience, we stand as a trusted partner, ready to take on your projects with confidence.

Elevate your surfaces to perfection with the Sandblasting Cabinet and achieve the highest quality in your projects. Contact us for more information and discover how we can help make your surfaces perfect.

Sandblasting cabinets produced by BF BLAST according to the needs; It can be optimized as a rotary table, drum, or double door. The table below shows the types of vacuum cabinets:

| CODE | SAND CAPACITY | CABINET DIMENSIONS (L*W*H) | PRESSURE | NOZZLE |

| BF VK Mini | 5 LT | 500*500*500 | 4-6 bar | 6-8 mm |

| BF VK 900 | 10 LT | 700*800*1000mm | 4-6 bar | 8 mm |

| BF VK 1000 | 15 LT | 1000*1000*1500mm | 4-6 bar | 8 mm |

| BF VK 1500 | 40 LT | 1500*1500*1000 | 4-6 bar | 8 mm |